Master quality assurance in bulk eyelash manufacturing with our guide. Explore standards, control measures, and certifications for safe and consistent lash production.

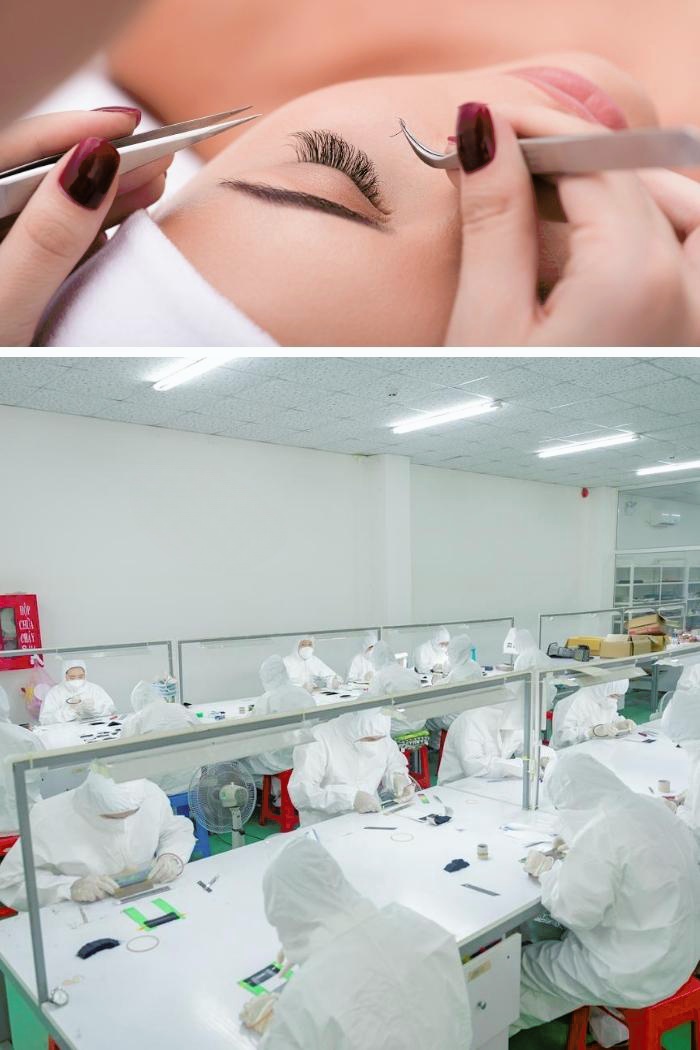

Unlock the keys to success in your lash business with expert insights on mastering quality assurance in bulk eyelash manufacturing. Delve into industry benchmarks and implement effective quality controls for unparalleled excellence. Elevate your brand with superior lash quality.

Understanding Quality Standards in Bulk Eyelash Manufacturing

Navigate the intricacies of bulk eyelash production by grasping the essence of quality standards. Uncover the secrets to decoding industry benchmarks and ensuring compliance with safety regulations. Elevate your understanding of impeccable lash quality.

Decoding Lash Industry Quality Benchmarks In Bulk Lash Manufacturing

In the dynamic world of bulk eyelash production, deciphering and comprehending industry-specific quality benchmarks is paramount. This section sheds light on the nuances of these benchmarks, offering a comprehensive guide for manufacturers striving for excellence.

- Quality Benchmarks: The length, thickness, and curl consistency of eyelashes stand as pivotal benchmarks, ensuring visual uniformity. Manufacturers meticulously measure and control these attributes, guaranteeing lashes meet precise specifications.

- Safety and Wearability: Beyond aesthetics, safety benchmarks play a crucial role. Rigorous testing for adhesion strength ensures lashes withstand daily wear, providing durability and satisfaction to consumers. Additionally, hypoallergenic properties are meticulously examined to safeguard users against adverse reactions.

- Regulatory Compliance: Quality benchmarks in quality assurance in bulk eyelash manufacturing extend to regulatory compliance, encompassing regional and international standards. Adhering to these guidelines is not just a legal obligation but a commitment to ethical, quality-driven manufacturing. This ensures the production of eyelashes that meet industry regulations and consumer expectations.

In decoding industry-specific quality benchmarks for bulk eyelash manufacturing, manufacturers gain a profound understanding of the parameters that define excellence. By meticulously adhering to these benchmarks, they not only meet industry standards but also exceed consumer expectations, fostering a reputation for quality and reliability.

Adhering to Eyelash Extension Safety Regulations In Bulk Manufacturing

In the realm of bulk eyelash manufacturing quality assurance, adherence to eyelash extension safety regulations is paramount. These regulations wield significant influence, ensuring the overall quality and safety of bulk eyelashes.

- Ingredient Analysis for Safety Certification: Rigorous analysis of ingredients ensures compliance with safety certifications, safeguarding consumers against harmful substances. Manufacturers meticulously vet each component, prioritizing safety and integrity in every lash produced.

- Irritation Testing for Hypoallergenic Properties: Comprehensive irritation testing evaluates the hypoallergenic properties of eyelashes, minimizing the risk of adverse reactions. By adhering to these regulations, manufacturers prioritize consumer safety, fostering trust and confidence in their products.

- Compliance with Regional and National Safety Standards: Adherence to regional and national safety standards is non-negotiable in bulk eyelash manufacturing. Manufacturers meticulously follow these regulations, guaranteeing the production of safe and reliable eyelashes for global markets.

In navigating eyelash extension safety regulations, manufacturers uphold the highest standards of quality assurance. By meticulously adhering to these regulations, they ensure the production of safe, reliable, and high-quality bulk eyelashes, fostering consumer trust and loyalty.

Implementing Effective Quality Control Measures For Bulk Eyelash Manufacturing

Elevate your bulk eyelash manufacturing prowess with insights on implementing effective quality control measures. Dive into the intricacies of material quality control, ensuring impeccable lash materials. Master precision in production processes to guarantee consistent and superior bulk lash quality.

Material Quality Control For Successful Bulk Eyelash Extension Manufacturing

In the realm of bulk eyelash manufacturing quality assurance, meticulous material quality control is the cornerstone of success. This section unravels the critical process of assessing and ensuring the quality of raw materials, with a focus on mink, silk, and synthetic lashes.

- Assessing Mink Lashes for Premium Quality: A rigorous examination ensures mink lashes meet premium quality standards, guaranteeing a luxurious and sought-after final product for consumers.

- Ensuring Silk Lashes Meet Stringent Specifications: Material quality control meticulously examines silk lashes, ensuring they meet stringent specifications, leading to a consistent and high-quality eyelash line.

- Quality Checks on Synthetic Lashes for Uniform Excellence: Rigorous quality checks on synthetic lashes guarantee uniform excellence, establishing them as a reliable and versatile option in bulk eyelash manufacturing.

In the realm of bulk eyelash manufacturing, material quality control, especially for mink, silk, and synthetic lashes, is non-negotiable. By ensuring each type meets premium quality standards, stringent specifications, and uniform excellence, manufacturers lay the foundation for a successful and reputable lash line.

Precision in Production Processes For Bulk Lash Production

In the pursuit of bulk eyelash manufacturing quality assurance, achieving precision in production processes is pivotal. This section unveils the critical importance of ensuring standardized and precise manufacturing processes for maintaining consistent bulk eyelash quality.

- Standardized Procedures for Uniform Quality: Standardized procedures are implemented to guarantee uniform quality, ensuring each eyelash meets stringent specifications for length, thickness, and curl consistency.

- Defect Detection Protocols for Flawless Products: Rigorous defect detection protocols are in place, meticulously identifying and correcting any imperfections during the production process, ensuring the delivery of flawless eyelashes.

- Automation Tools Enhancing Quality Control: Integration of advanced automation tools streamlines quality control processes, enhancing precision and efficiency in bulk eyelash manufacturing.

In the intricate landscape of bulk eyelash manufacturing, precision in production processes ensures standardized procedures, defect detection protocols, and the integration of automation tools. This commitment to precision guarantees a consistent and high-quality output, solidifying the reputation of an eyelash manufacturer in the competitive lash market.

FAQs On Quality Assurance In Bulk Eyelash Manufacturing

- What are the benefits of using a quality assurance program for bulk eyelash manufacturing

Implementing a quality assurance program in bulk lash extension manufacturing ensures consistent product quality. It enhances customer satisfaction, fosters brand reputation, and minimizes the risk of defects, ultimately leading to increased sales and profitability.

- What are the most common quality issues seen in bulk eyelash extensions

Common quality issues in bulk eyelash extensions include inconsistent lash length, thickness, or curl. Adhesion problems and variations in color or texture are also observed. Rigorous quality control measures address these issues, ensuring a flawless and uniform product.

- What are the potential risks of using low-quality bulk eyelash extensions

Using low-quality wholesale eyelash extensions poses potential risks such as irritation and allergic reactions. These lashes may have poor adhesion strength, leading to premature shedding. Additionally, subpar materials may compromise safety and wear time, impacting the overall user experience.

- What should I do if I receive bulk lashes that are not up to quality standards

If you receive bulk lashes that are not up to quality standards, promptly contact the eyelash extension manufacturer or supplier. Provide detailed information about the quality issues and request a replacement or refund. Maintaining clear communication ensures a swift resolution and upholds your commitment to delivering top-notch eyelash products to your customers.

- Where can I find more information about quality assurance in bulk eyelash manufacturing

For more information about lash production’s quality, explore beauty industry standards from organizations like the International Organization for Standardization (ISO) and Good Manufacturing Practices (GMP). Refer to regulatory bodies such as the EU Cosmetics Regulation and the US FDA for specific guidelines. Additionally, engage with reputable industry publications and connect with experienced suppliers or manufacturers for valuable insights.

Conclusion

Mastering quality assurance in bulk eyelash manufacturing is the key to elevating your lash business. Rigorous adherence to industry standards, meticulous material quality control, and precision in production processes ensure consistent, high-quality eyelash extensions. Uphold customer trust, enhance brand reputation, and guarantee success in the competitive lash market.