This blog explores how technological advancements in wholesale eyelash manufacturing shape eyelash production’s future, from automated production processes to innovative materials. Discover now!

The wholesale eyelash manufacturing industry has recently experienced remarkable technological advancements. These innovations have transformed the way eyelashes are produced, resulting in improved quality, efficiency, and customization options. This blog will delve into the world of technological advancements in wholesale eyelash manufacturing and unveil cutting-edge technologies shaping the industry.

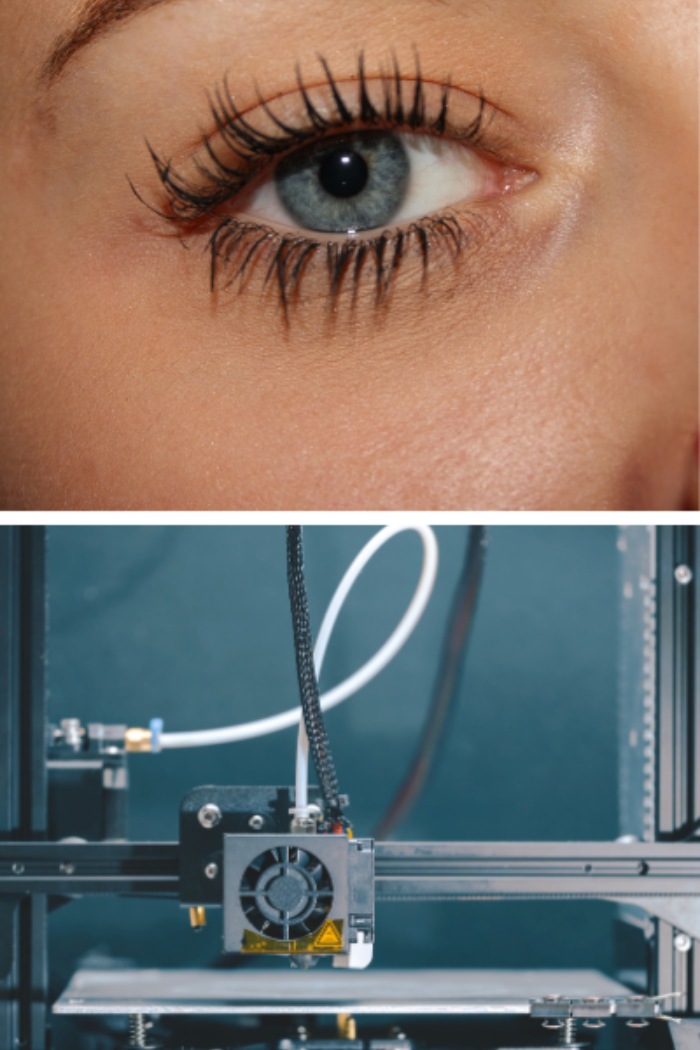

3D Printing and Customization

Advancements in 3D printing technology have significantly impacted the manufacturing of eyelashes, providing new possibilities for customization and design. This technology allows manufacturers to create unique and high-quality eyelashes that cater to individual preferences, leading to enhanced customer satisfaction and a wider range of eyelash options in the wholesale market.Here are some key aspects of the advancements in 3D printing for eyelash manufacturing:

Advantages of 3D Printed Eyelashes in Wholesale Manufacturing

3D printed eyelashes in wholesale manufacturing offer several advantages over traditional manufacturing methods. Here are some of the key advantages:

- Customization: 3D printing allows for a high level of customization. Eyelashes can be designed and printed in various shapes, lengths, and styles to cater to customer preferences. This opens up many possibilities for unique and personalized eyelash designs, which can be a significant selling point for wholesale manufacturers.

- Rapid prototyping and production: This technological advancements in wholesale eyelash manufacturing enables rapid prototyping, allowing manufacturers to iterate and refine their designs quickly. This can save time during product development and help bring new products to market faster. Once the design is finalized, 3D printing can facilitate fast and efficient production, enabling manufacturers to effectively meet high-demand periods.

- Material versatility: 3D printing offers a wide range of material options, including flexible and lightweight materials suitable for eyelashes. Manufacturers can experiment with different materials to find the optimal combination of comfort, durability, and aesthetics for their eyelashes.

- Reduced waste and environmental impact: Traditional manufacturing processes often generate significant waste due to material cutting and shaping. In contrast, 3D printing is an additive manufacturing process which only uses the necessary amount of material for each eyelash, minimizing waste. Additionally, 3D printing often requires less energy and emits fewer pollutants than traditional manufacturing methods, making it a more environmentally friendly option.

It’s important to note that while 3D printed eyelashes offer these advantages, there may still be limitations and challenges to address, such as ensuring product quality and consistency, optimizing production speed, and managing the learning curve associated with implementing 3D printing technology.

Implementing 3D Printing in Eyelash Production

Implementing 3D printing in eyelash production involves several steps. Here’s a general outline of the process:

- Design and modeling: The first step is to create a digital 3D model of the desired eyelash design. This can be done using 3D modeling software or by scanning an existing eyelash design to create a digital replica. The design should consider factors such as lash length, curl types, thickness, and overall aesthetics.

- Material selection: Choose the appropriate material for 3D printing the eyelashes. Consider factors such as flexibility, durability, and comfort. Various lash materials are suitable for 3D printing eyelashes, including flexible filaments like TPU (thermoplastic polyurethane) or special resins designed for cosmetic applications.

- Preparing the 3D printer: Set up the 3D printer for printing. This involves calibrating the printer, ensuring the print bed is level, and loading the appropriate filament or resin.

- Post-processing: Remove the printed eyelashes from the print bed once the printing is complete. Depending on the material used, post-processing steps may be required. This can include cleaning the eyelashes to remove any support structures, sanding or polishing to achieve a smooth finish, and potentially dyeing or coloring the lashes.

It’s important to note that implementing 3D printing in eyelash production requires investment in 3D printing equipment, materials, and expertise. It may also involve a learning curve as you familiarize yourself with the technology and optimize the process for efficient and high-quality production.

Smart Manufacturing and Quality Control

Smart manufacturing refers to integrating technological advancements in wholesale eyelash manufacturing, such as artificial intelligence (AI), Internet of Things (IoT), data analytics, and automation, into the manufacturing process. On the other hand, quality control in wholesale eyelash production focuses on ensuring that the products meet the desired quality standards. By leveraging smart manufacturing techniques, quality control can be significantly enhanced. Here are some ways in which smart manufacturing can improve quality control:

IoT and Automation: Enhancing Efficiency in Eyelash Manufacturing

IoT (Internet of Things) and automation technologies can be leveraged to enhance efficiency in eyelash manufacturing processes. Here are some ways in which these technologies can be applied:

- Automated production processes: Automation technological advancements in wholesale eyelash manufacturing, such as robotic systems, can be employed to automate repetitive and labor-intensive tasks in eyelash manufacturing. For example, robotic arms can handle and assemble eyelash components, reducing manual labor and increasing production speed. Automated processes can also improve consistency and precision, ensuring each eyelash meets the desired specifications. Customization in wholesale eyelash extensions can further enhance these automated processes, allowing for personalized designs and styles tailored to the preferences of clients and beauty professionals.

- Quality control and inspection: IoT sensors and machine vision technologies can be employed for automated quality control and inspection processes. Sensors can capture data during production, such as temperature, humidity, and other relevant parameters, which can be analyzed to identify potential quality issues. Machine vision systems can inspect eyelashes for defects, ensuring consistent quality standards. Automated quality control processes reduce reliance on manual inspections, enabling faster and more accurate identification of defects, thus improving manufacturing efficiency.

- Data analytics for process optimization: IoT-generated data can be analyzed using advanced analytics techniques to identify patterns, trends, and inefficiencies in the manufacturing process. Manufacturers can gain insights into factors that affect production efficiency, such as cycle times, machine utilization, and material wastage. With this information, process optimization strategies can be developed to streamline operations, reduce bottlenecks, and improve overall efficiency.

By integrating IoT and automation technologies into eyelash manufacturing processes, manufacturers can achieve higher levels of efficiency, reduce production costs, minimize errors, and enhance overall productivity. However, it is essential to consider data security, system integration, and workforce training when implementing these technologies.

Optimizing Manufacturing Processes in Data Analytics and Predictive Maintenance

Optimizing manufacturing processes through data analytics and predictive maintenance involves utilizing data-driven insights to improve efficiency, reduce costs, and enhance overall operational performance. Here’s how these approaches can be applied:

- Data collection and integration: Collect relevant data from various sources within the manufacturing process, such as sensors, equipment, production lines, and quality control systems. This data may include temperature, pressure, machine performance, production rates, and quality metrics. Ensure that the data is properly integrated and stored in a centralized system for analysis.

- Predictive maintenance: Implement predictive maintenance strategies based on data analytics and machine learning algorithms. By analyzing equipment performance data, manufacturers can predict when maintenance is required to prevent unexpected breakdowns. This enables proactive scheduling of maintenance activities, reducing unplanned downtime, optimizing equipment utilization, and extending the lifespan of machinery. Predictive maintenance also helps avoid costly repairs and enhances overall production efficiency.

- Real-time monitoring and control: Implement real-time monitoring systems that leverage data analytics to provide instant visibility into key performance indicators (KPIs). Real-time dashboards and alerts can help monitor process parameters, quality metrics, and production targets, enabling timely interventions to address deviations and ensure targets are met. Real-time monitoring also facilitates proactive decision-making and efficient resource allocation.

By leveraging data analytics and predictive maintenance in manufacturing processes, organizations can optimize operations, reduce costs, enhance product quality, and improve overall efficiency. However, it’s crucial to have a robust data infrastructure, ensure data security and privacy, and foster a culture of data-driven decision-making to fully realize the benefits of these approaches.

FAQs about Technological Advancements in Wholesale Eyelash Manufacturing

- How has automation impacted wholesale eyelash manufacturing?

Automation has had a significant impact on wholesale eyelash manufacturing. Manufacturers can achieve higher production volumes and faster turnaround times by automating various stages of the production process, such as cutting, shaping, and packaging. Automation also reduces the risk of human error and ensures greater consistency in the quality of the eyelashes. This has led to increased productivity, cost savings for manufacturers, and improved product quality for consumers.

- How have technological advancements improved the quality of wholesale eyelashes?

Technological advancements in wholesale eyelash manufacturing have greatly improved the quality of wholesale eyelash extensions. For instance, advanced manufacturing equipment and processes allow for more precise and consistent cutting and shaping of the eyelashes, resulting in uniformity and better overall quality. Moreover, innovative materials and adhesive technologies have enhanced the durability and longevity of eyelashes, making them more resistant to wear and tear. These advancements have contributed to higher customer satisfaction and increased demand for wholesale eyelashes. Evaluating a lash supplier reputation is crucial in ensuring that these technological advancements translate into reliable and high-quality products for customers and businesses alike.

- Have technological advancements reduced the cost of wholesale eyelash manufacturing?

Yes, technological advancements have often led to a reduction in the cost of wholesale eyelash manufacturing. Automation, for example, can significantly reduce labor costs by replacing manual tasks with machines. Improved manufacturing processes also increase efficiency, reduce waste, and optimize the use of raw materials, resulting in cost savings. Additionally, technological advancements enable manufacturers to scale up production, which can lead to economies of scale and further cost reductions.

- How have technological advancements impacted wholesale eyelash manufacturing?

Technological advancements have revolutionized wholesale eyelash manufacturing in several ways. Firstly, advanced machinery and equipment have streamlined production, increasing efficiency and reducing manufacturing time. Automation has also improved the precision and consistency of eyelash production, resulting in higher-quality products. Additionally, technological innovations have enabled the development of new materials and techniques, allowing manufacturers to create a broader range of eyelash styles and designs.

- What are some examples of technological advancements in wholesale eyelash manufacturing?

There are several notable technological advancements in wholesale eyelash manufacturing. One example is advanced manufacturing equipment, such as computer-controlled machines that precisely cut and shape eyelashes. Another example is the application of 3D printing technology, which allows for creating intricate and customized designs. Additionally, advancements in adhesive technology have led to the development of more durable and long-lasting eyelash adhesive products.

Conclusion

The wholesale eyelash manufacturing industry is experiencing a technological revolution. These advancements, from automated production processes to 3D printing, advanced materials, and smart manufacturing, are driving the industry forward. As technology continues to evolve, we can expect even more exciting innovations that will shape the future of wholesale eyelash manufacturing, providing beauty professionals and clients with unparalleled options and quality. Partnering with a reputable REFINELASH supplier ensures access to cutting-edge technologies and high-quality products that meet the evolving demands of the industry.